Research & System

Hyunbo Co., Ltd. has over 30 years of experience and know-how.

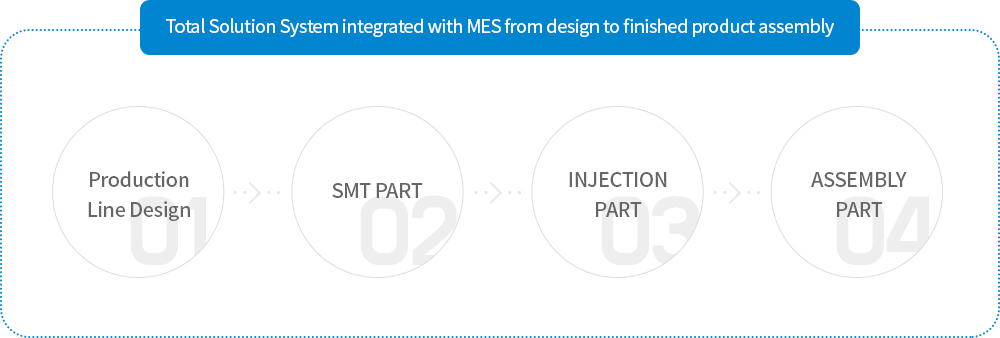

From receiving raw material to shipping product, all production processes are linked to MES to achieve zero defect rate.

MES field

What is MES?

MES System

Manufacturing Execution System

It enables the optimization of all production activities from order to completion of the product. To this end, MES guides, initiates, responds, and reports on all work activities in the plant using accurate data in real time. This increases the efficiency of work and processes in the plant

MES System

Benefits of MES

Benefits 1

Optimal decision support is possible through integration of manufacturing sites, systems, production activities, and real time information.

Benefits 2

It contributes to business management by improving productivity and quality, reducing costs.

-

Resource allocation status

Hyunbo MES

MES System

Features of MES in Hyunbo

MES Features 1

Wider range of applications than the industry average of SMEs

MES System

Applying MES in Hyunbo

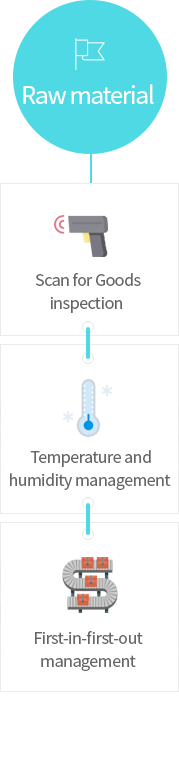

Material Management

① Continuous management from receipt of material to disposal.

② First In First Out system

③ Prevent the use of wrong material, expired material, and any other not described in work instruction.

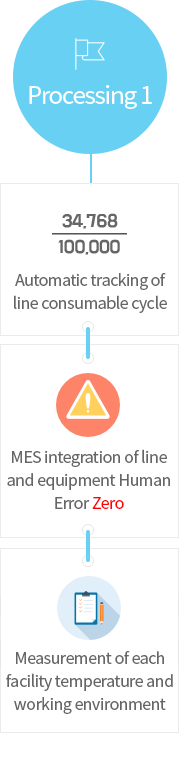

Machine Facility Management

① Daily inspection and preventive maintenance activities.

② Notification of consumable part replacement with function to prevent exceeded usage without replacement.

③ For operating environment management, Machine can’t be operated if any value is out of the normal range by using sensors in machine.

Man Personnel Management

① If an operator doesn’t respond at specified time, the system prevents further processes. It helps operator to focus and prevent the machine unattended.

Method management

① Operator can check equipment operating status, material and input by PDA

② Integration of MES with equipment, MES determines materials and operating environment Line operation judgment.

③ Excellence traceability with unique laser engraving per product. All the data can be traceable and accessible.

④ Work environment temperature and humidity data recording.

MES - 4M

We will inform you about the four methods of management.

- τ Man (Personnel Management)

- 1) Personnel, work efficiency management (Labor Efficiency)

- 2) Man-machine Ratio

- 3) Personnel, Multi-functional Player (Multi-functional Player)

- τ Machine (Equipment Management)

- 1) Equipment, improving utilization rate, failure rate reduction, equipment performance Equipment life

- 2) Equipment, daily inspection, preventive maintenance activities

- 3) Equipment - Equipment specification (Spec) management

- τ Material

- 1) Materials - safety inventory, availability / disposal inventory management

- 2) Materials - Import & Export Management, Identification & Tracking Management

- 3) Materials - raw materials (imports), semi-finished products (process), finished products (final)

- τ Method (Method Management)

- 1) Method - How to cultivate work capacity: Training and Practice

- 2) Method - Work standards (work order and method description per process)

- 3) Method - Inspection standards (Inspection sequence and method description per process